Super Liquefaction™: Enzyme Tank Treatments, Marketing Hype, and Real Waste Science

Posted by Happy Campers Store on Oct 9th 2025

Super Liquefaction™: Enzyme Tank Treatments, Marketing Hype, and Real Waste Science

RV Holding Tank Care · Science & Mythbusting

RVers have been told for years that “rapidly liquefying waste” is the gold standard for clean tanks. That promise—built on jar-test videos and enzyme/bacterial claims—became the default narrative. But does faster breakdown actually mean cleaner tanks, better dump flow, or happier septic systems? In this science-backed guide, we unpack the Super Liquefaction™ myth—where it came from, why it’s misleading, and how real RV waste science tells a different story.

What many users discover later: when it comes to odor control—the original reason holding-tank treatments were created—enzyme products often fall short (especially in heat). After switching, many RVers report stronger smells or recurring odor issues, realizing that rapid breakdown isn’t the same as true odor neutralization. Happy Campers was designed with that core goal in mind: odor-free performance first, with balanced chemistry that keeps tanks calm and clean without overactive “Super Liquefaction™.”

What We Mean by Super Liquefaction™

Definition: Super Liquefaction™ is the overactive breakdown of RV holding-tank solids into a soupy slurry (sludge) via enzyme/bacterial additives—marketed as “proof” of superior efficiency. It looks dramatic in a jar, but it doesn’t automatically translate to cleaner tank walls, better drain performance, or healthier septic systems.

“Liquefied waste changes what’s floating, not what’s sticking. A liquefied tank isn’t necessarily a clean or efficient tank.”

How “Rapid Breakdown” Became the Go-To Marketing Hook

1) The Jar Demo Effect

Because most RVers can’t see inside their tanks, a quick jar demo acts like “proof.” Add treatment, watch solids vanish, assume “cleaner tank.” It’s compelling theater—but it ignores tank geometry, stagnation, and the reality of surface films.

The Popular “Dog Food Test” Video Explained

One of the most-watched comparison videos online shows eight RV black tank treatments—including enzyme formulas and mineral-based products like Happy Campers—tested in plastic tubs with water and dog food over six days. The goal: to see which treatment turns waste into a smooth brown slurry (sludge) the fastest.

Key takeaway: While some enzyme treatments in this test have a cool visual breakdown of proteins, that rapid “Super Liquefaction™” doesn’t produce a cleaner dump or better tank performance in real use. Happy Campers’ mineral-based formula continues to deliver the same reliable flow and odor control—without over-digesting waste into slurry (sludge) or creating septic imbalance. The dog-food test looks dramatic, but it’s not representative of real-world RV waste science.

Here’s an actual AI-generated overview pulled from a Google Search result about RV black tank care:

“For most RV owners, rapid waste breakdown is the primary goal for their black and gray water tanks. However, other strategies exist, and the best method depends on how you use your RV. The goal of rapid breakdown is to liquefy solid waste and toilet paper into a slurry that can be easily and completely flushed out when you dump the tank.”

Even artificial intelligence has learned to assume that “rapid liquefaction” is the gold standard — proof that repetition in marketing and content has shaped not only consumer perception, but the data that trains AI itself.

We know... these photos aren’t exactly dinner-table conversation. But holding tanks aren’t glamorous — and real waste flow is the only way to show what’s really happening down there. ?

If you’re eating, maybe finish that first. Otherwise, dive in — this is the science of clean, odor-free RV living, and it's important to monitor your tank evacuation using clear sewer hose elbows to know what's gong on.

Jar Tests vs. Real Tanks: The Truth Behind What You See

If you’ve watched the popular “dog food” jar tests online, you may have noticed something interesting: in those jars, Happy Campers often looks like it’s not doing much at all. The enzymes in competing products create frothy, swirling, fast-moving liquid that seems to “melt” waste on camera — while Happy Campers appears calm, almost inactive.

But jars aren’t tanks. Real RV holding tanks are sealed, dark, and experience agitation, temperature swings, and hydraulic flow — none of which happen in a jar. In the real world, Happy Campers works quietly and efficiently: it neutralizes odor compounds, stabilizes tank chemistry, and keeps solids from sticking or compacting. You don’t see flashy bubbling, but you feel the difference when it’s time to dump.

In jar tests, enzyme products win the “show.” In your RV, Happy Campers wins the dump — steady, consistent evacuation, smooth flow, and odor-free operation. That’s real performance.

Can You Tell Which Is Which?

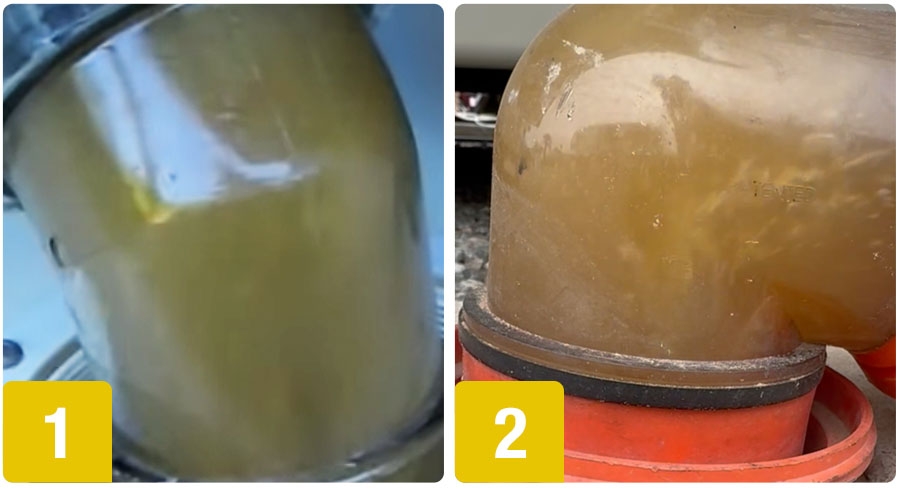

The side-by-side photos below show two actual black tank dumps — one treated with Happy Campers, the other with a popular enzyme-based treatment. Both tanks were maintained properly and both dumped cleanly. Visually, they look almost identical — and that’s exactly the point.

Can you tell which tank used Happy Campers? Most people can’t — and that’s the point.

In real tanks, performance isn’t about showy liquefaction. It’s about consistent, odor-free dumps and residue-free walls. That’s where Happy Campers quietly excels.

- Happy Campers maintains a balanced mineral environment that prevents buildup and neutralizes odors.

- Enzyme liquefaction may look dramatic when you're watching enzymes chew through TP and dog food in minutes, but doesn’t guarantee clean tank walls or accurate sensors.

In real-world RV use, Happy Campers performs exactly as it should — efficiently, odor-free, and without overactive liquefaction.

*For educational comparison only. Both images show real black tank dumps under similar conditions. Visual appearance alone cannot determine cleanliness, odor control, or sensor accuracy.*

2) Repetition Creates Belief

Years of videos, blogs, affiliates, and product pages anchored “faster = better.” The leap that liquefaction must improve flow and prevent residue went largely unchallenged (our bad).

Why “Super Liquefaction™” Doesn’t Mean a Clean RV Tank (Science Explained)

A) Biofilms & EPS stick to surfaces

Even fully liquid waste forms biofilms—microbial communities embedded in sticky extracellular polymeric substances (EPS) that adhere to tank walls, fittings, and probes. Biofilms are ubiquitous in low-flow water/waste systems and require chemical and/or mechanical action to remove. Liquefaction alone doesn’t strip films.

- Biofilms trap fine fibers, fats, and minerals—creating long-term residue.

- Residual film is the enemy of clean dump flow and reliable sensors.

B) Liquefaction can increase conductivity (sensor trouble)

Breaking solids into ions and dissolved organics raises electrical conductivity. Probe-style tank sensors detect conductivity between electrodes; a more conductive slurry (sludge) can falsely register “full” or give stuck readings—even in tanks that look clean on rinse.

C) Stagnation beats spectacle

RV tanks are holding tanks. Waste sits for hours or days with dead zones (corners, flats, sensor recesses). Liquefied or not, residues deposit in low-velocity zones unless rinsed or agitated—standard behavior in stagnant wastewater hydraulics.

What Independent Demos Actually Show (and What They Don’t)

D) The Missing Third-Party Proof

While many RVers and product reviewers report that certain enzyme-based treatments appear to break down waste into a slurry more completely—especially in short-term or visual “jar test” settings—there’s still no robust, independent, RV-specific research showing that this rapid breakdown leads to cleaner tank walls, faster dump flow, or better long-term maintenance results.

Most available claims remain vendor-driven or anecdotal, and demonstrations are typically conducted in small, transparent containers—not full-scale RV holding tanks where geometry, head depth, slope, and residue formation behave very differently.

In real-world use, even when enzyme treatments appear to liquefy waste more aggressively, users do not experience a measurably faster or cleaner dump. Side-by-side in actual tanks, Happy Campers’ mineral-based formula provides the same reliable evacuation and odor-free performance—without over-digesting waste into slurry or stressing septic systems.

Real-World Demo Observations: What These Tests Actually Show

A recent independent comparison used ~32-gallon polyethylene tubs with toilet paper, bananas, dog food, and water to compare an enzyme “liquefaction” treatment vs. a surfactant mix. The setup looked convincing—but several design details don’t match a sealed RV black tank:

- Taller-than-reality vessels: The tubs were ~2½ feet deep—much deeper than typical RV tanks (≈8–12″). That extra depth changes head dynamics and makes drainage appear slower.

- Outlet not flush to the floor: The 3″ drain bulkhead sat through the sidewall, leaving a lip. Real RV gate valves mount flush to the sloped tank floor, so solids don’t need to “climb” to exit.

- Lids removed for viewing: Draining with the lid off eliminates the brief vent-assist surge you get in a sealed, vented tank (the “whoosh” that helps sweep solids to the outlet).

- Slower flow despite 3″ hardware: With side outlets, elbows, and no surge, the tubs drained noticeably slower than a real holding tank would under the same volume.

- Large residue remained in both tubs: After the first dump, both setups left substantial solids on the bottom. In a real RV tank, that much leftover waste would be a red flag for flow, odor, and sensors—evidence the demo’s geometry, not chemistry, limited evacuation.

A single rinse made a big difference for both tubs—another reminder that water volume, slope, and flow energy drive evacuation. That aligns with field practice: dump, then rinse/refill to protect tank health, regardless of treatment type.

*Based on an independent 32-gallon tub comparison (2024–2025), summarized here for educational analysis.*

Do Enzyme Treatments Improve RV Dump Flow? (The Physics)

Short answer: not meaningfully. Once waste behaves like a fluid, dump performance is governed mainly by outlet size and liquid height (head), not how “soupy” the contents are.

Gravity & head pressure set the pace

In gravity outflow, velocity relates to the square root of the fluid head above the outlet. Through a 3-inch gate valve and hose, geometry dominates. Reducing viscosity beyond the point of fluidity gives diminishing returns.

Scouring vs. “slurry (sludge)”

Mild turbulence and suspended solids during dumping help scour surfaces. Hyper-thin “soup” can reduce wall shear, leaving films behind. In practice, adequate water, agitation while traveling, and periodic rinsing matter far more than chasing dramatic liquefaction.

Why Liquefaction Can Worsen Probe-Sensor Readings

- Higher conductivity from dissolved ions makes it easier to complete the circuit → false “full.”

- Biofilms coat probes, altering or shorting the electrical path.

- Low-flow zones around probes let residue persist unless rinsed.

This is an electrical/surface phenomenon, not a “speed of breakdown” issue.

What Happens to Enzyme-Liquefied Waste in Septic Systems

Septic basics

Conventional septic tanks rely on steady settling and balanced anaerobic digestion. Introducing a slug of enzyme-rich “super liquefied” waste can destabilize that equilibrium by suspending solids, boosting dissolved organics, and shifting microbial balance.

Observed risks (from wastewater/septic guidance)

- More dissolved organics (higher BOD) → extra load on downstream aerobic zones and drain fields.

- Solids carry-over when suspended fines bypass settling → potential drain-field stress.

- Microbial imbalance & extra sludge → surplus microbes eventually die, adding to pump-out volume.

EPA and university extension programs commonly advise against routine septic additives (bacteria/enzymes/chemicals) because systems already have ample microbes and additives can cause unintended consequences.

A Better Alternative: Mineral-Based RV Tank Science That Works

1) Odor control first

Neutralize odor compounds without fueling dramatic biology. Mineral-based chemistry keeps tanks calm and scent-free (you can’t film “no smell,” but your nose knows).

Takeaway: You can’t film “no smell,” but your nose knows. Real-world results show that effective odor neutralization and steady flow matter more than creating a perfect slurry. Happy Campers keeps tanks stable, scent-free, and balanced without overactive “Super Liquefication™.”

Visuals can deceive—but your nose doesn’t lie. In real tanks, “Super Liquefaction™” might look active, but Happy Campers proves that odor control and stable chemistry are what truly define clean performance.

2) Prevent residue (the real enemy)

Residue is a surface problem. Use adequate water, agitate while traveling, and rinse when possible. Avoid over-enzymatic slurry (sludge) that leaves sticky films (EPS/biofilm).

3) Respect gravity

Dump performance is about liquid volume and head height through a 3-inch outlet—not turning tanks into “waste soup.”

4) Be septic-smart

Follow mainstream guidance: avoid “enzyme boost” additives for septic systems; they’re unnecessary and can harm performance.

Keep learning: enzyme vs. mineral RV tank treatments • how to reset a black tank • odor control for RV holding tanks

Myth vs. Reality (At-a-Glance)

“Rapid liquefaction = cleaner tank.”

RealityLiquefaction changes the liquid, not the walls. Biofilm and EPS still adhere and build residue without rinsing or agitation.

“More liquid = faster dumps.”

RealityDump rate is dominated by gravity, outlet size, and head height once contents are fluid. Thinner soup doesn’t beat geometry.

“Liquefaction reduces sensor problems.”

RealityMore dissolved ions raise conductivity, which can trigger false “full” readings on probe sensors. Films can also coat probes.

“Enzyme slurries are septic-friendly.”

RealityGuidance often advises against additives. Slurries can suspend solids, increase BOD, upset microbial balance, and add sludge.

Quick Glossary

Biofilm: A sticky surface layer of microorganisms embedded in EPS that adheres to walls and sensors.

EPS (Extracellular Polymeric Substances): Gel-like “glue” secreted by microbes; drives film formation and disruption.

Slurry (Sludge): Liquid laden with very fine suspended solids; looks smooth but still coats surfaces.

BOD (Biochemical Oxygen Demand): A measure of dissolved organics; higher BOD increases treatment burden downstream.

Head (Head Pressure): The height of liquid above the outlet; key driver of gravity dump velocity.

Selected References & Guidance

• U.S. EPA & University Extensions: routine septic additives (bacteria/enzymes/chemicals) are not recommended; systems already contain ample microbes and additives can suspend solids or stress drain fields.

• Biofilm/EPS literature: biofilms persist and foul surfaces in low-flow water/waste contexts; removal typically requires chemical or mechanical intervention.

• Fluid-mechanics primers (gravity outflow): once contents are fluid, outlet size and head height govern dump rate; further liquefaction yields diminishing returns.

Selected References & Guidance

- U.S. EPA – “Should You Add Anything to Your Septic Tank?”

- University of Minnesota Extension – “Maintaining Your Septic System”

- National Library of Medicine – Biofilm Basics

- Engineering Toolbox – Flow of Liquids from Tanks

- PubChem – Hydrogen Sulfide (H₂S) Odor Compound Data

These external references support commonly accepted wastewater, biofilm, and septic science principles applied to RV holding tank care.

Note: The above reflects broadly accepted wastewater, biofilm, and septic guidance. For an even deeper dive, consult municipal wastewater texts and university extension publications on septic maintenance.

FAQ

What is Super Liquefaction™?

Our term for the overactive breakdown of RV tank waste by enzyme/bacterial treatments—creating a slurry (sludge) that looks clean in a jar but can leave residue on tank walls and sensors.

Do enzyme RV tank treatments really improve dump flow?

Not in a meaningful way once contents are fluid. Gravity, outlet size, and head height set the pace. Adequate water and rinsing beat “super soup.”

Is Super Liquefaction™ bad for septic systems?

It can be. Over-liquefied, enzyme-rich waste may suspend solids, increase dissolved organics (BOD), upset microbial balance, and add sludge—contrary to mainstream septic guidance.

What actually keeps an RV tank clean?

Odor control, balanced chemistry, adequate water, movement/agitation, and periodic rinsing. Focus on flow and residue prevention, not theatrics.